Home » 2020

Yearly Archives: 2020

Q4 2020 Newsletter

This quarter’s issue of On the Forefront looks at four areas to audit when seeking a contract manufacturer able to support rapid product development. Our President, Walter Tarca, reflects on this year’s challenges and accomplishments. Finally, we introduce EZYSWAB, a nasopharyngeal swab utilized for Covid-19 PCR testing, which we manufacture in Singapore. Read the full issue here.

Achieving Speed and Quality

The battle against COVID-19 has created a niche need for companies able to support product development cycles that cut months off traditional product development timelines. Achieving that speed should not translate to abandoning the quality control checks and balances necessary to meet regulatory requirements and achieve superior quality. Like the driver and pit crew relationship in Gran Prix racing, cutting that much time out of a product development cycle requires close collaboration between medical device manufacturer and the contract manufacturer. Everyone needs to understand their roles, project requirements and key milestones. Not surprisingly, selecting a contract manufacturer with well-defined processes, broad capabilities, and significant design and manufacturing expertise can provide substantial advantages in this area.

Forefront Medical Technology, a specialty contract manufacturer with a focus in disposable diagnostic, drug delivery systems and medical device systems, feels there are four areas that can help in achieving speed and quality in time-sensitive product development efforts. They are:

- A robust process for ensuring close collaboration during product development

- Internal tooling design and fabrication capabilities

- Vertically-integrated manufacturing capabilities

- Regulatory expertise.

This whitepaper looks at each of these areas and suggests questions for auditing contract manufacturer capabilities in assessing competency. Read the full whitepaper here.

Q3 2020 Newsletter

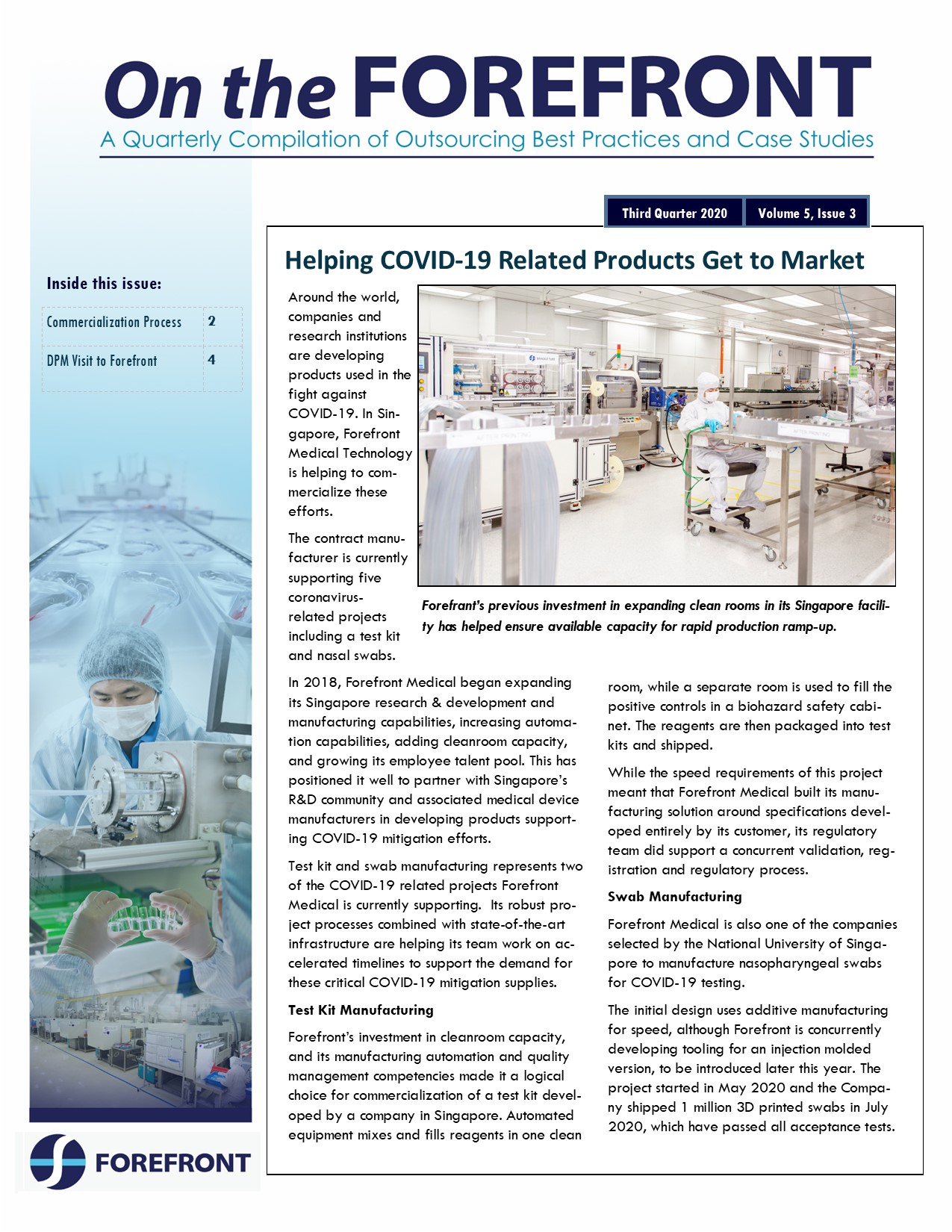

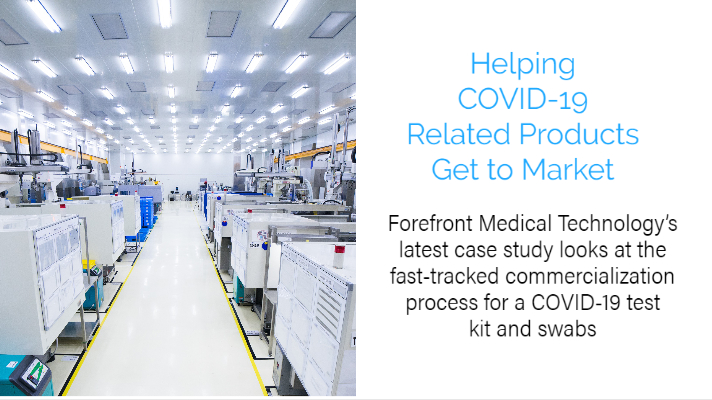

This quarter’s On the Forefront newsletter looks at two COVID-19 related projects that Forefront has currently supported with rapid production ramp-ups. Forefront’s robust process for project commercialization is discussed in detail. There is also a brief overview of the recent visit of Singapore’s Deputy Prime Minister to Forefront’s Singapore headquarters and production facility. Read the full issue here.

Forefront Helps in the Fight Against COVID-19

Around the world, companies and research institutions are developing products used in the fight against COVID-19. In Singapore, Forefront Medical Technology, a specialty contract manufacturer with a focus in disposable diagnostic, drug delivery systems and medical device systems, is helping to commercialize these efforts.

The contract manufacturer is currently supporting five coronavirus-related projects including a test kit and nasal swabs. In 2018, Forefront Medical began expanding its Singapore research & development and manufacturing capabilities, increasing automation capabilities, adding cleanroom capacity, and growing its employee talent pool. This has positioned it well to partner with Singapore’s R&D community and associated medical device manufacturers in developing products supporting COVID-19 mitigation efforts. Read the full case study here.

Q2 2020 Newsletter

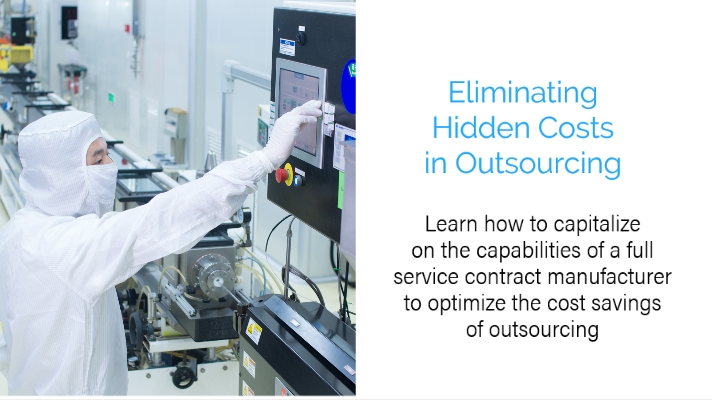

This quarter’s On the Forefront newsletter includes a case study that discusses the ways that changing the manufacturing strategy for a specialized drug infusion set reduced cost and improved overall quality. Forefront’s ability to help customers reduce total cost by optimizing the value stream to eliminate inefficiencies is also covered. Finally, there is a roundup of Forefront’s latest news coverage. Read the full issue here.

Eliminating Hidden Costs in Outsourcing

Outsourcing discussions often focus on manufacturing capabilities or regional labor costs. However, that narrow focus often allows hidden costs related to transactional redundancies and other inefficiencies to slip in.

In addition to lowering the labor cost and eliminating the need for investment in plant and equipment, outsourcing to a full service contract manufacturer frees up working capital, by eliminating the need for money to be tied up in raw material and work-in-process inventories. The contract manufacturer typically purchases material and carries the costs of production during the conversion cycle, billing the OEM as product ships. Administrative transactions are reduced since the contract manufacturer manages the bulk of the supply chain. There may be additional savings in overhead personnel as contract manufacturer resources eliminate the need for large manufacturing support organizations. If logistics are optimized, unnecessary transit legs may be eliminated. In short, when the value stream is optimized, many unnecessary, hidden costs are eliminated and throughput increases. In this case study, Forefront Medical Technology, discusses the ways that changing the manufacturing strategy for a specialty drug infusion set reduced cost and improved overall quality. Read it here.

Q1 2020 Newsletter

This quarter’s issue of On the Forefront looks at Forefront Medical Technology’s six week journey in restarting its China manufacturing following the COVID-19 infection in China. It also looks at Forefront’s worldwide network of facilities and its ability to support a broad range of new product development technologies in its Singapore engineering and manufacturing facility. Read the full issue here.

Forefront Featured in Medical Product Outsourcing

Medical Product Outsourcing magazine’s January/February issue looks at outsourcing trends. Learn more about ways Forefront’s ability to support products which require both mechanical and electromechanical design & assembly improves quality while reducing product development time and cost. If you are going to MDM West Feb. 11-13, be sure to visit Forefront in Booth 2385. You can access the full article here.

Learn More About Forefront’s Ability to Support Electromechanical Projects

Contract manufacturers serving the medical device market typically divide into two distinct segments: electronics contract manufacturing and precision engineering contract manufacturers. Electronics contract manufacturers build both printed circuit board assemblies (PCBAs) and electromechanical systems. Precision engineering contract manufacturers focus on non-electronic products requiring molding, metal fabrication, extrusions or other custom components. There are distinct skill sets in each type of supplier. Electronics contract manufacturers are typically experts in the assembly and test issues related to PCBAs and associated box builds. Precision engineering contract manufacturers are expert in tooling development, materials qualification and assembly automation.

The reasons these distinct supplier segments exist is because medical devices segregated neatly into each segment. However, as electronics become more pervasive there is more convergence. One good example of this is drug delivery systems. The dispensing mechanism is electromechanical, but there is also a substantial amount of tubing and disposable components associated with the system.

A core benefit of either type of contract manufacturer is access to shared resources of production at a fraction of the cost of developing that production infrastructure inhouse. Customers pay for the shared machine time they use instead of having to absorb the full costs of inhouse equipment they may not be fully utilizing.

The disadvantage of segregating contract manufacturing services to either electromechanical or precision engineering disciplines is that creates silos in the product development phase, increases complexity of the supply chain and may add redundant cost structures or markups to the final assembly and fulfillment process.

Forefront Medical Technology believes that offering both electromechanical and precision engineering services is fundamental to achieving lowest total cost of ownership in contract manufacturing. In the drug delivery system example discussed above, the ability to address both the electromechanical, tubing and disposable component elements of the equation enables customers to leverage synergies throughout the product development and commercialization process. This whitepaper looks at the benefits of this type of full service outsourcing approach in terms of product development, regulatory considerations, supply chain management, production and assembly processes, and fulfillment. Read the full whitepaper here.

Use This Free Pass To Visit Us at MDM West 2020

Forefront Medical Technology will be exhibiting at MDM West in Anaheim Feb 11-13 in booth #2385. Use promo code SPECIAL to get a free expo pass and 20% off the conference. Register here. Be sure to ask about our electromechanical support capabilities.

Forefront Medical Technology will be exhibiting at MDM West in Anaheim Feb 11-13 in booth #2385. Use promo code SPECIAL to get a free expo pass and 20% off the conference. Register here. Be sure to ask about our electromechanical support capabilities.